21-VLL Series Vertical Motors

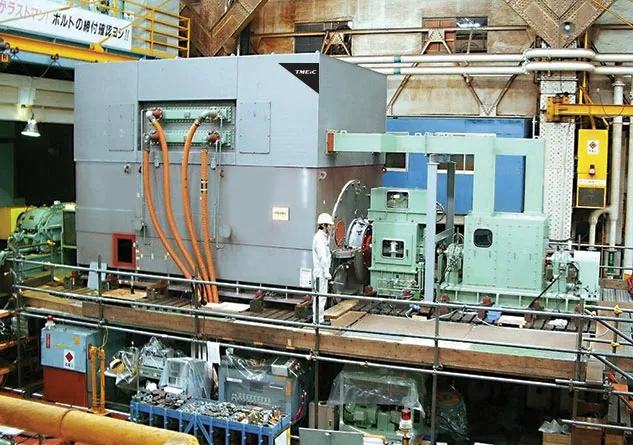

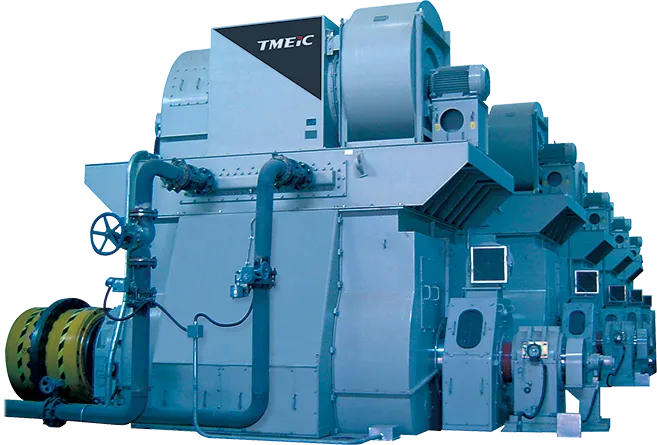

The 21-VLL series three-phase medium-voltage motors are designed for large capacity applications.

Downloadable Resources

Introducing the VLL Series: High-Capacity Vertical Motors

The 21-VLL series three-phase medium-voltage motors are designed for large capacity applications.

- UP to 6500 kW (8,700 HP)

- WPII, TEAAC and TEWAC and custom frames

- Designed to meet worldwide standards

- Fabricated steel plate construction

- C5 steel lamination

Engineered for Reliability and Serviceability

The 21-VLL series is designed with features that maximize reliability while simplifying maintenance and operation. Application-specific thrust bearings and optional non-reversing ratchets ensure upper bearing performance under varying loads. A precision-built, split-core stator reduces core loss and assembly time, while the copper bar rotor is optimized for pump applications with enhanced starting torque and robust construction. Modular cooling options—including water-to-air, air-to-air (IP55), and open air circuits—support a wide range of operating environments with durable, corrosion-resistant materials.

Features & Benefits

Excellent Electrical Performance

- Electromagnetic field analysis

- Heat conduction analysis

- Air flow system analysis

Insulation & Cooling

- Angular contact ball bearings (self-cooled)

- Spherical roller thrust bearings (self-cooled, air-cooled, water-cooled, oil-cooled

- Tilting pad thrust bearings (air-cooled, water-cooled, oil-cooled

- Drip-proof, NEMA Weather Protected

Noise Reduction

- The latest technology reduces noise to 80 dBa and less, and vibration level to 1.8 mm/sec

- Lower noise and vibrations address health and reliability concerns

Efficiency

- Increased efficiency

- Higher power factor

- Superior starting characteristics

Insulation

- Advanced VPI Insulation System

- Greater capacity of Improved insulation withstanding higher surges of power

- Inverter drive operation is an option

Specifications

| Standard Specifications | Remarks | |

|---|---|---|

| Rated Output Power | 650 kW – 6,500 kW, depending on the number of poles | Cooling method may affect output range: IC611 TEAAC: 5,000 kW max. output IC81W TEWAC: 6,500 kW max. output IC01 ODP: 6,500 kW max. output |

| Rated Voltage | 3,000 or 3,300 4,000 or 4,160 6,000 or 6,600 10,000 or 11,000 | Options: 2.3 kV, 2.4 kV, 13.2 kV, 13.8 kV |

| Frequency | 50 Hz, 60 Hz | Adjustable speed with an inverter is an option |

| Number of Poles | 12 – 28 poles | 8 poles, 10 poles or over 30 poles can be manufactured |

| Applicable Standards | IEC60034-1 (General) JEC or NEMA IEC60034-1 or JEC-2137 IEEE112 Method F or JEC-2137 | Motors can be manufactured to meet NEMA, IEC, BS, AS or Japanese Standard JEC-2137 Exn: Non-sparking Exe: Increased safety Exp: Pressurized eG3, eG2: Increased safety fG3, fG4: Pressurized |

| Reference ambient temp. | Maximum: +40° C; Minimum: -20° C | Motors for high (50° C) or low (-50° C) temperature environments are available |

| Insulation class | F temperature insulation | VPI (vacuum pressured impregnation) insulation system |

| Temperature rise limit | Temperature rise limit of the stator windings when ambient temperature is 40° C uses B rise ETD method 85k, 90K | F class temperature rise is available (1) more than 5,000 kW (2) less than 4,000 kW |

| Service factor | 1.0 SF | 1.0 SF (B-rise)/1.15 SF (F-rise) is an option |

| Noise | 80dB(A): design value (4 points average value) | A low-noise motor can be manufactured, depending on the number of poles, and size of the monitor |

| Protection/cooling system | Totally-enclosed type: IP55-IC611, IC81W Open drip-proof type: IP22, IP24-IC01 | Protection and cooling methods may be selected in accordance to the installation conditions or environment |

| Starting method | Full voltage starting (Direct on line): normally considered ±10% voltage | Option - reduced voltage starting using reactor or autotransformer Indicate permissible starting kVA |

| Rotation direction | Uni-direction is standard Bi-directional is an option | Motor with a non-reversing ratchet cannot be run in reverse |

| Shaft end | Single shaft extension; straight shaft with parallel key | If the fluxional torque value is large when starting or during operation, the key way and shaft dimensions may be changed |

| Cooling water for TEWAC motor | Cooling water: Temperature: Max. 35°C Shutoff pressure: Max. 0.7 MPa Water quality: Fresh water for industrial use Tube shape: Single tube with plate fins Tube material: Seamless phosphorus deoxidized copper tube (JIS C1220) | Indicate if supplied water temperature is higher than 35° C A double tube can be manufactured Water quality (polluted fresh water, sea water), determines tube material - tube material may be changed to Cu-Ni (JIS C 7060T), or higher grade material |

| Finished color | Munsell notation 2.5PB6/2 | Other colors available |

| Accessories | Standard accessories include: Winding R.T.D.s (Pt-0°C-100): Qty. 6 Bearing R.T.D.s (Pt-0°C-100): Qty. 2 or 3 Space heater, maintenance ladder, simple platform, shaft end key, drain plug, grounding bolt | Other devices available as options: CT, surge arresters, surge capacitor, vibration detectors, dial thermometer, etc. |

| Test and Inspection | Factory tests carried out based on JEC2137 or IEEE112, IEEE85 Standard test results are provided Insulation test (High voltage and insulation resistance) Characteristic calculation results Vibration measurement Temperature rise test (first unit only) | Performance criteria: Unless otherwise specified, the tolerance approved by IEC60034-1 or JEC-2137 will be applied to the guaranteed value Indicate when a witness test is required |

Request a Quote

Request a Quote

Product request a quote form