Case Study Oil & Gas

Case Study: Oil & Gas Refinery Compression

A large refinery used gas turbines to drive two compressors. The turbines generated nitrogen oxides (NOX), noise pollution, and required more maintenance than electric motor drives. The refinery evaluated electric motors and hydraulic variable speed gearboxes, vs. electric drives, and chose an electric drive as the best solution.

The refinery’s new approach was to:

- Replace the two gas turbines with two electric motors of 30,000 hp, and use one LCI adjustable speed drive for motor starting and speed control.

- Use gear boxes to increase the speed input to the compressors from the 1,800 rpm motor speed.

- Use the adjustable speed drive to start one motor and synchronize it with the 13.8 kV bus.

- Employ switchgear to put this motor across the line and run the compressor at constant speed.

- Use the adjustable speed drive to start the second motor and continuously vary the speed of the second compressor to obtain the flow required by the process.

Advantages of the Drive System

Very High Reliability

The LCI has built-in channel and component redundancy allowing operation with a single failure without any reduction in power output.…

Eliminate Air & Noise Pollution

Gas turbine exhaust NOX and noise are avoided completely, producing an environmentally-friendly installation. The electrical drive system, therefore, does not…

Energy Savings

The LCI provides higher energy efficiency than either gas turbines or hydraulic variable speed drives. In addition, the synchronous motors…

Increased run time compared to turbine

Electric drives and AC motors require much less maintenance and down time than gas turbines. Drive availability is the highest…

Adjustable Speed Drive System One-Line Diagram

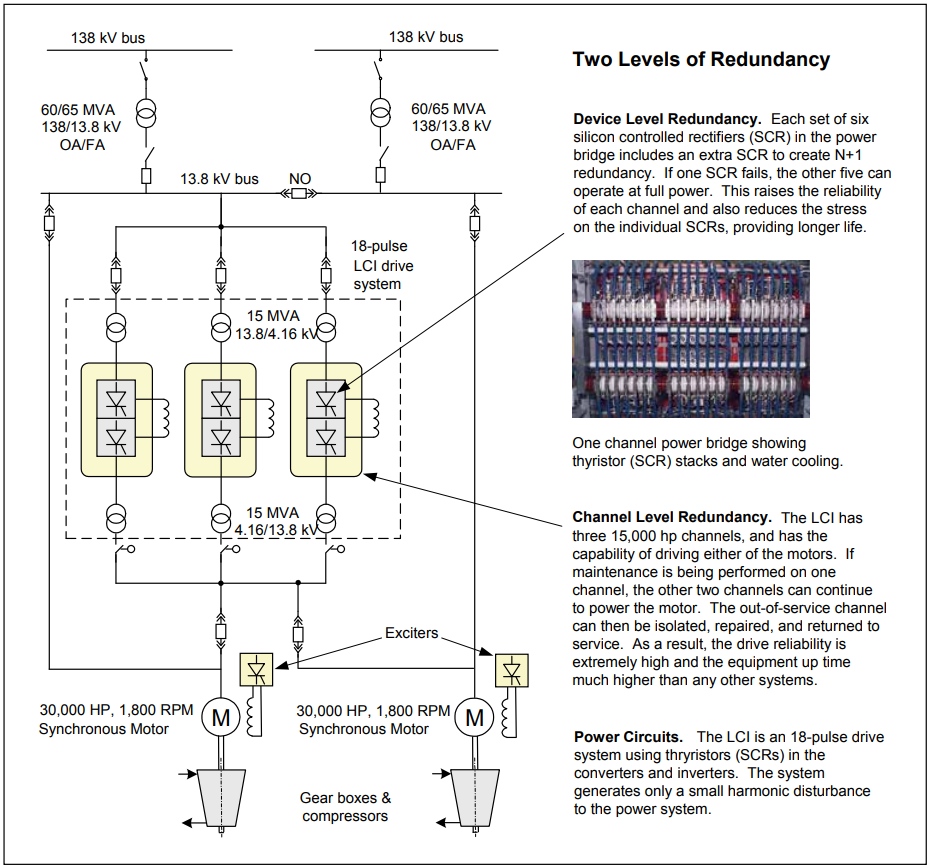

The LCI (Load Commutated Inverter) was selected for this drive application. It is a medium voltage drive and operates at 4.16 kV. Transformers drop the voltage from 13.8 kV, and after the drive, transformers increase the voltage to 13.8 kV to supply the motors. The drive has two levels of redundancy as shown in the diagram.